Add to Cart

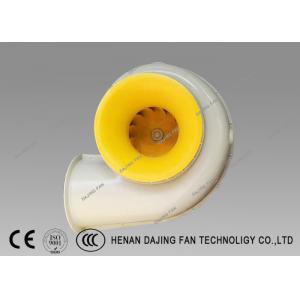

Industrial Hot Air FRP Centrifugal Fan Customized Size Ventilator Fan

The fan is made of polyester glass fiber reinforced plastic. The centrifugal fan is a new type of anti-corrosion fan with the characteristics of high strength, light weight, good corrosion resistance, not easy aging, low noise, multiple specifications and many applications. The fan is suitable for discharging corrosive gas with a certain concentration, and can also be used as general building ventilation for ventilation.

| Industrial Hot Air FRP Centrifugal Fan Customized Size Ventilator Fan | |||

| Centrifugal fan | Air Flow | 600~15000 | m3/h |

| Pressure | 240~3500 | Pa | |

| Rotating speed | 2900/1450 | r/min | |

| Material | FRP | ||

| Motor | Power | 0.55~7.5 | kw |

| Voltage | 220/380/440 | v | |

| Frequency | 50/60 | hz | |

1. The impeller is logarithmic linear design, made by the backward tilting integral molding method, to reduce loss and increase efficiency

2. The impeller is made of pure glass steel, which has completely changed the traditional carbon steel lined glass steel manufacturing process;

3. The bearing box with humanized design reduces the loss, prolongs the service life of the bearing, and is convenient for maintenance;

High intensity

Fan body adopts an FEA theological design structure. The fan is molded from high-quality FRP material with advanced formula and relatively small thermal expansion coefficient by using a mold, so that stable structure and high intensity are achieved.

High efficiency and energy saving

The fan adopts backward curved wheel with high balancing level and high efficiency. In combination with housing designed by CFD flow field simulation and inlet Venturi pipe, fan efficiency is over 69%, can reach 90% in maximum, and high-efficiency and energy-saving running of the fan is ensured.

Centrifugal fan production process:

Case Show: